M20

Power Monitors

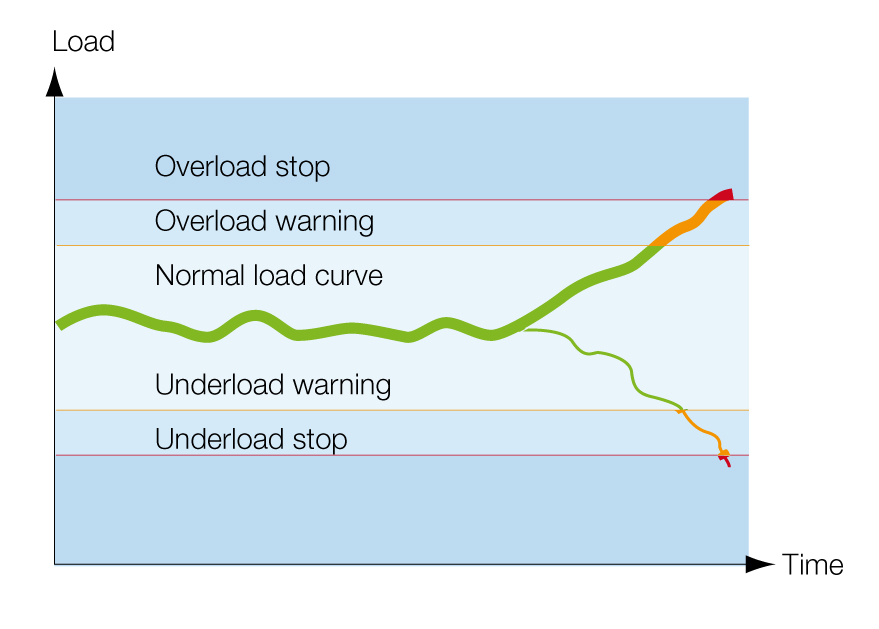

The Emotron M20 offers reliable, repeatable results for monitoring and protecting machines and processes against abnormal conditions. The M20 reduces overall maintenance costs by monitoring motor power to eliminate potentially hazardous conditions.

By using the motor as a sensor, the M20 eliminates the need for external sensors and extra cabling - and no holes need to be made in pipes! The result is increased reliability and reduced investment, installation, and maintenance costs.

Protecting with Shaft Power vs. Current

Unlike Amp / Current monitors, the Emotron M20 Shaft Power Monitor reliably protects motor driven equipment from abnormal process conditions such as pump dry run or jamming of a conveyor. In addition to providing inexpensive overload and underload protection, the M20 also provides process optimization and load control capability. Typical applications include conveyor monitoring, pump monitoring, and grinder monitoring.

The M20 provides protection against conditions such as:

Overload

Jams

Loss of Load

Misplaced parts

Looking for an alternative power monitoring solution? Click here to learn about our ProcessDefender process load monitor.

Key Features

Protection against underload and overload conditions

Scalable analog output

Simple setup in 3-seconds with AutoSet feature

Utilizes highly accurate and repeatable shaft power technology

Proven technology with over 500,000 units installed worldwide

Linear power profile provides reliable protection at any motor load

Product brochure: English | Spanish

Instruction Manual: English | Spanish

Quality Document: CE Certificate

Quality Document: UL Certificate

| Specifications | |

|---|---|

| Supply Voltage | 100-240 VAC / 380-500 VAC / 525-690 VAC |

| Frequency | 50 - 60 Hz |

| Rated Current | Up to 999 Amps via current transducer |

| Protection Class | IP20 |

| Approvals | CE, UL, cUL |

M20 in Your Industry

Aggregate & Mining

Protection against damage and downtime in crusher, conveyor and other applications found in Aggregate and Mining facilities.

Agriculture

Preventative maintenance for applications in the Agriculture industry.

Building Management

Prevent pump damage and failure with the Emotron M20.

Chemical & Petrochemical

Stop the damage to the equipment in your chemical plant before it occurs.

Food & Beverage

Preventative maintenance for pumps and other motor driven equipment found in Food & Beverage facilities.

Groundwater & Reclamation

Protect well and groundwater pumps against dry run conditions using the Emotron M20.

Marine

Ideal for protecting machines and processes in the Marine industry against unnecessary damage and downtime.

Oil & Gas

Stop the damage to the equipment in your Oil & Gas facility before it occurs.

Pharmaceutical

The Emotron M20 provides reliable protection for critical pharmaceutical processes driven by electric motors.

Process Manufacturing

Damage and downtime caused to your processing equipment can be costly. Prevent it before it occurs with the Emotron M20.

Sawmills

Prevent unnecessary damage to your Sawmill applications with the Emotron M20.

Water & Wastewater

The M20 acts as an electronic shearpin to protect against costly and unnecessary damage and downtime to rotary clarifiers and other motor driven equipment.

Get in touch.

Want more information about the Emotron M20 shaft power monitors? Please, drop us a line… we’re here to help!